hundom@hotmail.com

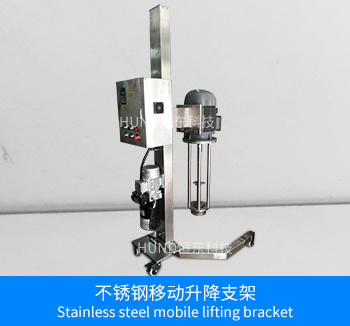

Name: mobile emulsifying head of electric lifting frame

Applicable materials: food, pharmaceutical, chemical, cosmetics, dairy

Model: ordinary motor (can be equipped according to customer needs)

If you are in a hurry, please call us.0086-13724810788 Nicole chen

- 尚宮家飾館

- 86403237

- 0086-13724810788

- 0086-13724810788

- hundom@hotmail.com

Tag:Stainless Steel Sanitary Batch Chemical Homogenizer High Shear Lifting Mixer

Introduction

When you want to produce stable emulsions and creams, wet and dissolve sticky powder (gums, thickeners, stabilizers), deagglomerate and disperse micro-phase solid ingredient (silicon dioxide, bentonite, titanium dioxide) into liquid without fish-eyes, or other similar tricky tasks, a traditional agitator is usually not able to achieve the expectation. However, the Batch Shear Mixer is what you should choose to do the job. Batch Shear Mixer is a high shear mixer for batch operation. For information about inline or continuous operation, please find us

Technical Parameters

| Model | Capacity(L/h) | Power(kw) | Speed(rpm) |

| HD-90 | 5-50 | 1.5 | 2800 |

| HD-100 | 50-100 | 2.2 | |

| HD-120 | 100-300 | 4 | |

| HD-140 | 200-800 | 7.5 | |

| HD-160 | 300-1000 | 11 | |

| HD-180 | 500-1500 | 18.5 | |

| HD-200 | 800-2000 | 22 | 1400 |

| HD-220 | 1000-3000 | 30 | |

| HD-240 | 1500-5000 | 37 |

Working Principles

High Shear Mixers work with a special designed stator/rotor working head. When it works, this stator/rotor head is able to draw the solids and liquids around it into its center, and then push them radially through the stator openings back to the tank. During this period, the solids and liquids are subject to an action of milling and shearing which is so intensive that they are deagglomerated, homogenized and dispersed into each other even though they are immiscible by traditional agitation.

Features

All wetted parts are grade 304 or 316 Stainless steel

Mechanical Seal for Sanitary Operation

Quick opening for easy cleaning

Hygienic Design.

Explosion-proof ABB Motor 3 Phase